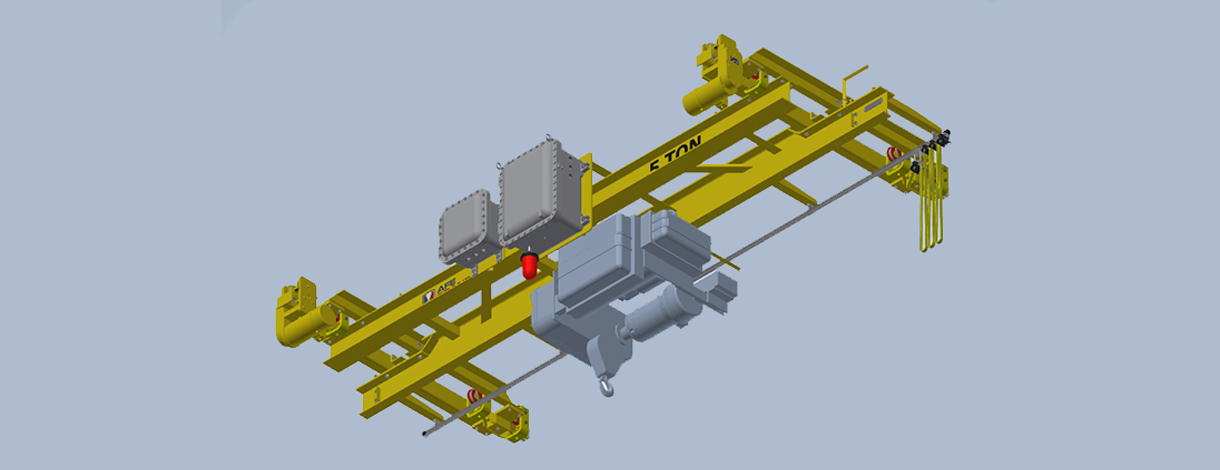

ACCO Explosion Proof Crane, Runway Extension

Cedar Falls, Iowa-based AFE Crane has installed a 5-ton capacity ACCO explosion proof crane for lifting bulk container bags in a hazardous area at a facility in Nebraska.

Cedar Falls, Iowa-based AFE Crane has installed a 5-ton capacity ACCO explosion proof crane for lifting bulk container bags in a hazardous area at a facility in Nebraska.

AFE, a distributor for ACCO Material Handling Solutions LLC, a manufacturer of material handling products, accepted a scope of work to install a replacement custom motorized underhung single girder crane and double the length of the runway from 60 ft. to 120 ft. The confidential site was classified because of electrical equipment installation in an atmosphere with combustible dusts representing a risk of fire and explosion.

The existing (ACCO) crane was built in 1999 and AFE, which conducts most of its installations in the U.S. Upper Midwest, was called upon to overhaul the lifting system, whilst conforming to the requirements of a crane system working in a hazardous environment, and to the tight confines of the building. The runway extension was required to allow access to new machinery in an extended work area.

The Class II, Group G, Division I crane has a 14 ft. span and 17 ft. 6 in. overall patented track bridge. The ACCO-Wright electric wire rope hoist offers 30 ft. per minute in single speed and a lift height of 66 ft. Nick Burns, applications engineer at AFE Crane, explained that this was the fastest possible without sacrificing headroom. The trolley is also single speed, offering 50 ft. per minute.

Jim Orme, District Sales Manager at ACCO, explained that Class II covers combustible dusts; Group G relates to grain dust; Division I means there is ignitable concentrations of dust present all of the time or some of the time under normal operation conditions.

He added: “All hoist components for use in classified areas are marked as such. The hoist motor, motor brake, conduit fittings, etc. are all labeled for Class 2, Group G, Division I. The Work-Rated hoist model includes an overload device as standard, as well as a Weston-style mechanical load brake as a secondary means of braking.”

Burns said: “We increased the speed for the new hoist due to the long lift. The installation provides high speed and capacity in line with the demands of the facility. Radio remote controls provide further safety and efficiency benefits as the end user can operate the crane and hoist at a safe distance from the hook.”

Burns said: “We increased the speed for the new hoist due to the long lift. The installation provides high speed and capacity in line with the demands of the facility. Radio remote controls provide further safety and efficiency benefits as the end user can operate the crane and hoist at a safe distance from the hook.”

Other notable features of the crane, which operates to Monorail Manufacturers Association (MMA) Class C duty cycle, include ACCO-Louden 585 style end trucks with eight (8) 4.5-in. diameter wheels, steel wheel drives and a 6 ft. 0 in. wheelbase. Dual gimbal rod assemblies, a suspension system for under-running crane runways, completed the installation.

Orme said: “Dual gimbal rod assemblies allow the system to ‘float’ with an allowance for the runway to move to adjust for movement in the building versus a ‘rigid’ suspension system. The system offered greater capacity and better headroom than a single rod alternative. It also allows for a higher tread elevation when headroom is critical. “Besides our standard offering, this installation demonstrates our ability to deliver material handling solutions to meet requirements of special applications.”